In the fast-evolving world of electronics and automation, having the right tools and technologies is crucial for efficiency and precision. Whether you are a hobbyist, an engineer, or a technician, understanding and utilizing these tools can significantly enhance your projects. This article will delve into four essential components: the USB I/O controller, the microstep stepper motor driver, the flat cable cutter, and model railway automation. These elements not only serve specific functions but also work together to streamline complex tasks, improve accuracy, and bring innovative ideas to life. Let’s explore each of these indispensable tools and how they contribute to modern electronics and automation projects.

USB I/O Controller

The USB I/O controller is a pivotal component in modern electronics, serving as the bridge between a computer and various peripheral devices. This versatile tool allows for efficient data exchange and control signals, making it indispensable for a wide range of applications.

A USB I/O controller enables seamless communication between your computer and external devices such as sensors, actuators, and other electronics. By converting digital signals to USB signals and vice versa, it facilitates real-time monitoring and control, which is essential for applications requiring precise data acquisition and automation.

One of the primary advantages of using a USB I/O controller is its plug-and-play capability. This feature allows users to connect and disconnect devices without needing to reboot the system, enhancing productivity and reducing downtime. Additionally, these controllers often come with user-friendly software interfaces that simplify configuration and management, even for those with limited technical expertise.

Moreover, USB I/O controllers are designed to support a wide range of protocols, making them highly adaptable to various project requirements. Whether you’re working on a home automation system, an industrial control setup, or a DIY electronics project, a USB I/O controller can provide the necessary connectivity and control.

In the realm of prototyping and development, the USB I/O controller shines by offering a reliable and efficient way to test and debug circuits. Its ability to interface with different sensors and modules makes it an invaluable tool for engineers and developers looking to streamline their workflow and achieve accurate results quickly.

Overall, the USB I/O controller is a key element in modern electronics, offering versatility, ease of use, and robust functionality. Its role in facilitating communication and control between computers and peripheral devices makes it a cornerstone for any project involving automation and data acquisition.

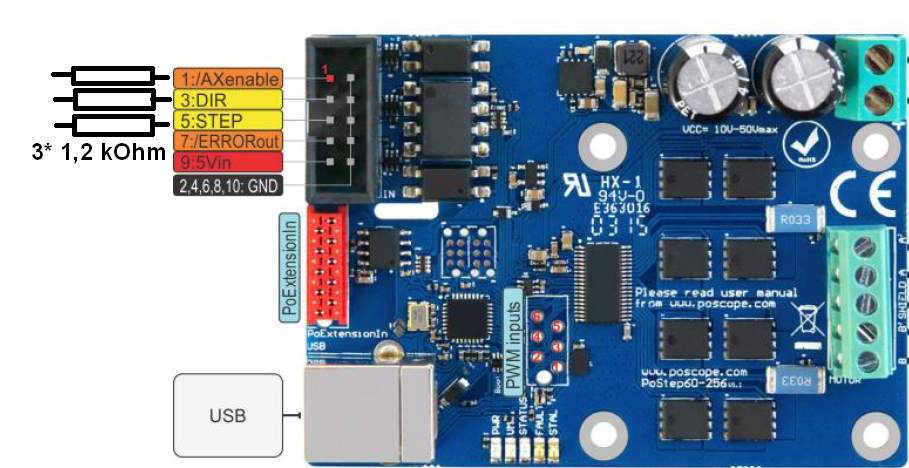

Microstep Stepper Motor Driver

In the realm of precision motion control, the microstep stepper motor driver stands out as a crucial component. This device is designed to control the movement of stepper motors, which are commonly used in applications requiring precise positioning and repeatable motion, such as CNC machines, 3D printers, and robotics.

A microstep stepper motor driver improves the performance of stepper motors by dividing each full step into smaller microsteps. This process, known as microstepping, allows for smoother and more precise motion control. By reducing the step size, a microstep stepper motor driver minimizes vibration and noise, which is particularly beneficial in applications where quiet and accurate movement is essential.

One of the key benefits of using a microstep stepper motor driver is its ability to provide high-resolution control. This high level of precision makes it possible to achieve finer details in projects that require exact positioning. For instance, in 3D printing, a microstep stepper motor driver ensures that the print head moves accurately to create intricate designs with high fidelity.

Additionally, microstep stepper motor drivers offer enhanced torque control. By distributing the torque more evenly across the motor’s steps, these drivers help maintain consistent performance even at lower speeds. This is critical in applications like CNC machining, where maintaining a steady and controlled motion is necessary to achieve precise cuts and engravings.

The versatility of microstep stepper motor drivers extends to their compatibility with various types of stepper motors and controllers. Whether you are working on a small-scale project or a complex industrial system, a microstep stepper motor driver can be tailored to meet specific requirements, providing reliable and efficient motion control.

Furthermore, the integration of advanced features such as programmable current limits, step resolution settings, and overheat protection make microstep stepper motor drivers user-friendly and robust. These features not only enhance the driver’s performance but also contribute to the longevity and reliability of the stepper motor system.

In conclusion, the microstep stepper motor driver is an essential tool for achieving precise and controlled motion in a wide range of applications. Its ability to enhance the performance of stepper motors through microstepping, high-resolution control, and improved torque management makes it a vital component in the toolkit of any engineer or hobbyist working with motion control systems.

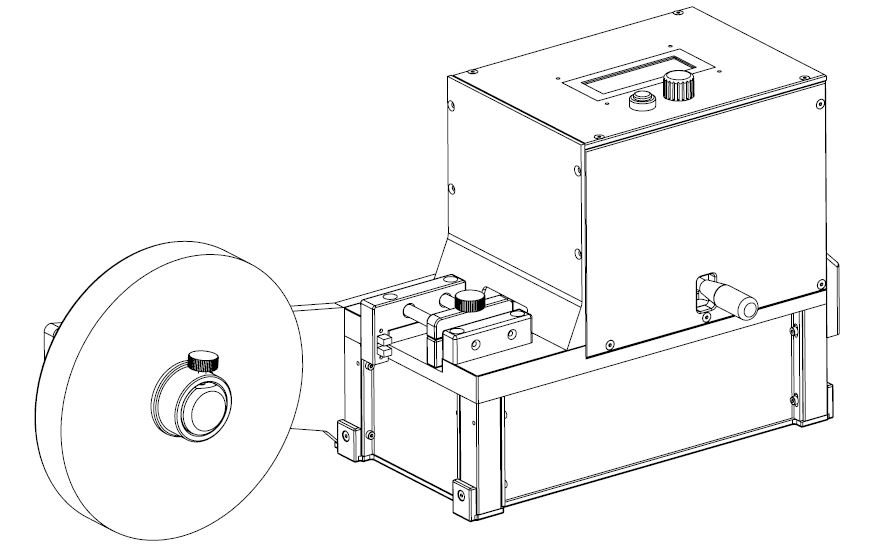

Flat Cable Cutter

When it comes to managing and customizing cable assemblies, a flat cable cutter is an indispensable tool. This device is specifically designed to cut flat cables, also known as ribbon cables, with precision and ease. Flat cables are commonly used in electronics due to their flexibility and ability to organize multiple conductors in a neat, parallel arrangement, making a flat cable cutter crucial for both professional and DIY projects.

One of the primary advantages of a flat cable cutter is its ability to provide clean, accurate cuts. Unlike traditional scissors or utility knives, a flat cable cutter is designed to cut through the multiple layers of insulation and conductors without fraying or damaging the cable. This precision is essential for maintaining the integrity and performance of the cable, especially in applications where reliable signal transmission is critical.

The flat cable cutter is also highly efficient, allowing for quick and consistent cuts. This efficiency is particularly beneficial in production environments where large volumes of flat cables need to be processed. By using a flat cable cutter, technicians can significantly reduce the time and effort required to prepare cables, increasing overall productivity.

Moreover, flat cable cutters are designed with user-friendly features that enhance safety and comfort. Many models come with ergonomic handles that provide a comfortable grip, reducing hand fatigue during prolonged use. Additionally, safety mechanisms such as blade guards help prevent accidental cuts, ensuring that users can operate the tool with confidence.

The versatility of flat cable cutters extends to their ability to cut various types of flat cables, including those with different widths and thicknesses. This adaptability makes them suitable for a wide range of applications, from computer and telecommunications equipment to automotive and industrial machinery. Whether you are assembling a custom cable harness or preparing cables for installation, a flat cable cutter ensures that your work is precise and professional.

In the context of electronics prototyping and repair, a flat cable cutter proves invaluable. The ability to quickly and accurately cut flat cables allows for seamless modifications and adjustments, enabling engineers and hobbyists to fine-tune their designs with ease. This level of precision is crucial for maintaining the reliability and performance of electronic systems.

In summary, a flat cable cutter is a must-have tool for anyone working with flat cables. Its ability to deliver precise, clean cuts, enhance productivity, and ensure user safety makes it an essential addition to any toolkit. Whether you are in a production environment or working on a DIY project, a flat cable cutter provides the accuracy and efficiency needed to handle flat cables effectively.

Model Railway Automation

Model railway automation represents the pinnacle of sophistication and realism in the world of model railroading. By incorporating advanced technologies, enthusiasts can transform their static layouts into dynamic, fully automated miniature worlds that mimic real-life railway operations with remarkable accuracy.

One of the primary components of model railway automation is the use of digital command control (DCC) systems. These systems allow operators to control multiple trains independently on the same track, providing greater flexibility and realism. With DCC, users can program routes, control speeds, and even operate accessories such as signals and turnouts, all from a single control unit. This level of control is essential for creating complex and engaging layouts.

Another key aspect of model railway automation is the integration of sensors and feedback systems. These technologies enable the layout to respond to the movement of trains in real-time. For example, infrared sensors can detect the presence of a train and trigger specific actions, such as changing signals or activating sounds. This interactivity enhances the realism of the layout, making it feel like a miniature version of a real railway network.

Automation software plays a crucial role in model railway automation, providing a user-friendly interface to design, control, and monitor the layout. These programs often include features such as route planning, scheduling, and automated operations, allowing for hands-free running of trains. With automation software, enthusiasts can create intricate scenarios and operations that would be impossible to manage manually, adding a new dimension to their hobby.

Model railway automation also benefits from advancements in wireless technology. Wireless controllers and mobile apps enable users to control their layouts remotely, offering convenience and flexibility. This capability is particularly useful in large layouts where physical access to all areas might be limited. Wireless technology also reduces the need for extensive wiring, simplifying the setup and maintenance of the layout.

Furthermore, model railway automation opens up opportunities for customization and personalization. Enthusiasts can incorporate unique elements such as automated lighting, sound effects, and even animated figures to bring their layouts to life. These additions not only enhance the visual appeal but also create an immersive experience for viewers.

In conclusion, model railway automation is a game-changer for hobbyists, providing tools and technologies that elevate the hobby to new heights. The integration of DCC systems, sensors, feedback mechanisms, automation software, and wireless technology allows for unprecedented control and realism. Whether you are a seasoned model railroader or a newcomer, embracing automation can transform your layout into a captivating and interactive miniature world.

Uniting Precision and Innovation in Electronics and Automation

In the ever-evolving landscape of electronics and automation, mastering the use of essential tools and technologies is key to achieving precision, efficiency, and innovation. The USB I/O controller, microstep stepper motor driver, flat cable cutter, and model railway automation each play a pivotal role in their respective domains, offering unique benefits and capabilities.

The USB I/O controller serves as a critical interface, enabling seamless communication between computers and peripheral devices, thereby facilitating real-time data acquisition and control. Its versatility and ease of use make it a cornerstone for a wide range of applications, from home automation to industrial control systems.

The microstep stepper motor driver enhances motion control by providing high-resolution steps and improved torque management. This device is indispensable for projects requiring precise positioning and smooth operation, such as CNC machines and 3D printers. Its advanced features ensure reliable and efficient performance, making it a favorite among engineers and hobbyists alike.

The flat cable cutter is essential for handling flat cables with precision and efficiency. Its ability to deliver clean, accurate cuts reduces time and effort in cable preparation, crucial for both production environments and DIY projects. The tool’s ergonomic design and safety features further enhance its usability and reliability.

Model railway automation represents the ultimate in hobbyist innovation, transforming static layouts into dynamic, interactive miniature worlds. By integrating digital command control systems, sensors, automation software, and wireless technology, enthusiasts can create highly realistic and engaging railway networks. This automation not only enhances the visual and operational aspects of model railroads but also provides endless opportunities for customization and creativity.

Together, these tools and technologies exemplify the advancements in modern electronics and automation. Whether you are building intricate model railways, developing precise motion control systems, or working on cutting-edge electronic projects, understanding and utilizing these components will significantly elevate your work. Embracing these innovations ensures that your projects are not only efficient and accurate but also at the forefront of technological progress.